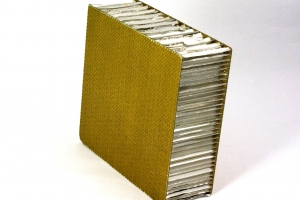

This aerospace sandwich panel is a masterpiece of stiff yet lightweight engineering, through both the materials from which it is made, and its ingenious design. Sandwich constructions like this can typically be found in the floors and walls of aircraft, as well as panels in high-performance cars, boats and the blades of wind turbines.

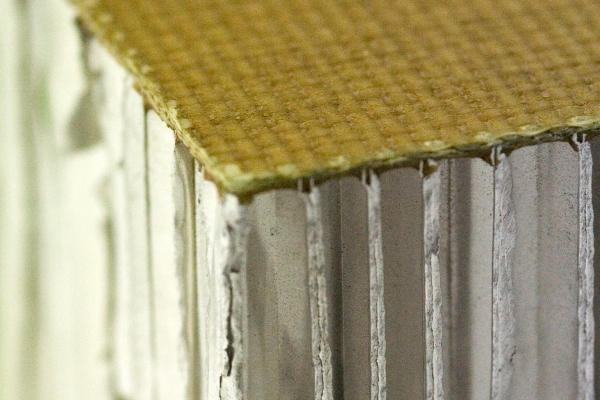

The ‘bread’ of the sandwich is made from two stiff layers of glass fibre-reinforced resin. In this composite, the resin matrix is tough and lightweight but relatively weak. Hair-like glass fibres are woven into a mat and embedded in the matrix which provides strength and stiffness. The result is a reinforced composite material which is strong, stiff, tough and lightweight. Due to the physics of bending forces acting across the sandwich, these parts of the structure do the heavy lifting when it comes to resisting the various stresses of service.

The ‘filling’ of the sandwich is a honeycomb made from lightweight aluminium foil. From beehives to bone, honeycombs are common structures in nature, where high strength and stiffness is required from low weight materials. They have been admired since ancient times; the Greeks celebrated their geometrical precision and honeycombs are thought to have inspired the engineering of the ribbing and hidden chambers in the dome of the Roman Pantheon. However, it wasn’t until 1915 that a German aircraft engineer by the name of Hugo Junkers first developed the concept of using honeycomb in laminate structures like this.

In this panel, the aluminium honeycomb separates the fibreglass sheets, giving the structure high bending rigidity. Although the aluminium foil is very thin, the honeycomb configuration is extremely strong when compressed in the direction of its vertical columns. The load is shared between these many vertical walls, and their regular geometrical arrangement allows the walls to support each other in the structure.

Finally, a structural adhesive plays the role of ‘margarine’ to bond the sandwich components together. It has the important job of transferring the forces between the glass fibre-reinforced resin ‘bread’ and the aluminium honeycomb ‘filling’ to ensure the sandwich remains as strong and stiff as it was designed to be.

Sample ID: 166

Particularities

- State

- Solid

- Compound

- Donated by

- King's College London

- Selections

- Categories

- Composite

- Curiosities

- Relationships

- Aerospace | Aluminium | Cellular | Discoloured | Foil | Geometry | Glass fibre | Honeycomb | Lamination | Light Weight | Resin | Sandwich | Stiffness | Strength

Add materials you find interesting to your own selections.

Use the  button to select a material and get started.

button to select a material and get started.